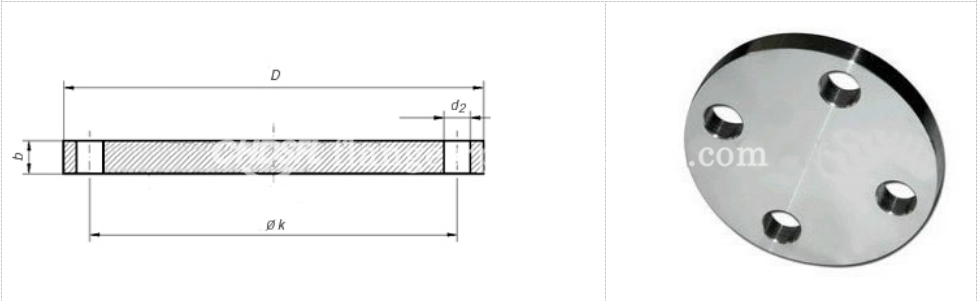

DIN 2527 BLIND FLANGE

PN6, PN10, PN16, PN25, PN40

Flange Dimensions & Approximate Masses

|

Germany standard flange DIN 2527 Blind flange Nominal Pressure 6 to 100 |

|||||||

|

Blindflansche Nenndruck 6 bis 100 |

|||||||

|

Brides plaines, pressions nominales 6 à 100 |

|||||||

|

DIN 2527 PN6 BLIND FLANGE |

|||||||

|

Rated |

Flange |

Screws |

Weight |

||||

|

D |

b |

k |

Number |

Thread |

d2 |

Shape B |

|

|

Kg |

|||||||

|

15 |

80 |

12 |

55 |

4 |

M 10 |

11 |

0.44 |

|

20 |

90 |

14 |

65 |

0.66 |

|||

|

25 |

100 |

14 |

75 |

0.83 |

|||

|

32 |

120 |

14 |

90 |

M 12 |

14 |

1.18 |

|

|

40 |

130 |

14 |

100 |

1.39 |

|||

|

50 |

140 |

14 |

110 |

1.63 |

|||

|

65 |

160 |

14 |

130 |

2.15 |

|||

|

80 |

190 |

16 |

150 |

M 16 |

18 |

3.44 |

|

|

100 |

210 |

16 |

170 |

4.22 |

|||

|

125 |

240 |

18 |

200 |

8 |

6.11 |

||

|

150 |

265 |

18 |

225 |

7.51 |

|||

|

200 |

320 |

20 |

280 |

12.31 |

|||

|

250 |

375 |

22 |

335 |

12 |

18.54 |

||

|

300 |

440 |

22 |

395 |

M 20 |

22 |

25.46 |

|

|

350 |

490 |

22 |

445 |

31.77 |

|||

|

400 |

540 |

22 |

495 |

16 |

38.49 |

||

|

500 |

645 |

24 |

600 |

20 |

60.10 |

||

|

DIN 2527 PN10 BLIND FLANGE |

|||||||

|

Rated |

Flange |

Screws |

Weight |

||||

|

D |

b |

k |

Number |

Thread |

d2 |

Shape B |

|

|

Kg |

|||||||

|

15 |

95 |

14 |

65 |

4 |

M 12 |

14 |

0,72 |

|

20 |

105 |

16 |

75 |

1,01 |

|||

|

25 |

115 |

16 |

85 |

1,23 |

|||

|

32 |

140 |

16 |

100 |

M 16 |

18 |

1,8 |

|

|

40 |

150 |

16 |

110 |

2,09 |

|||

|

50 |

165 |

18 |

125 |

2,88 |

|||

|

65 |

185 |

18 |

145 |

3,66 |

|||

|

80 |

200 |

20 |

160 |

4,77 |

|||

|

100 |

220 |

20 |

180 |

8 |

5,65 |

||

|

125 |

250 |

22 |

210 |

8,42 |

|||

|

150 |

285 |

22 |

240 |

M 20 |

22 |

10,4 |

|

|

200 |

340 |

24 |

295 |

16,5 |

|||

|

250 |

395 |

26 |

350 |

12 |

24 |

||

|

300 |

445 |

26 |

400 |

30,9 |

|||

|

350 |

505 |

26 |

460 |

16 |

40,6 |

||

|

400 |

565 |

26 |

515 |

M 24 |

26 |

49,4 |

|

|

500 |

670 |

28 |

620 |

20 |

75 |

||

|

DIN 2527 PN16 BLIND FLANGE |

|||||||

|

Rated |

Flange |

Screws |

Weight |

||||

|

D |

b |

k |

Number |

Thread |

d2 |

Shape B |

|

|

Kg |

|||||||

|

15 |

95 |

14 |

65 |

4 |

M 12 |

14 |

0,72 |

|

20 |

105 |

16 |

75 |

1,01 |

|||

|

25 |

115 |

16 |

85 |

1,23 |

|||

|

32 |

140 |

16 |

100 |

M 16 |

18 |

1,8 |

|

|

40 |

150 |

16 |

110 |

2,09 |

|||

|

50 |

165 |

18 |

125 |

2,88 |

|||

|

65 |

185 |

18 |

145 |

3,66 |

|||

|

80 |

200 |

20 |

160 |

8 |

4,77 |

||

|

100 |

220 |

20 |

180 |

5,65 |

|||

|

125 |

250 |

22 |

210 |

8,42 |

|||

|

150 |

285 |

22 |

240 |

M 20 |

22 |

10,4 |

|

|

200 |

340 |

24 |

295 |

12 |

16,1 |

||

|

250 |

405 |

26 |

355 |

M 24 |

26 |

24,9 |

|

|

300 |

460 |

28 |

410 |

35,1 |

|||

|

350 |

520 |

30 |

470 |

16 |

47,8 |

||

|

400 |

580 |

32 |

525 |

M 27 |

30 |

63,5 |

|

|

500 |

715 |

36 |

650 |

20 |

M 30 |

33 |

102 |

NOTE:

1. Facing according to DIN 2526

Flat face:

Form A, Face without any requirements

Form B, Face Rz=160, machined (not smoother than 40µm)

Raised Face:

Form C, Face Rz=160, machined (not smoother than 40µm)

Form D, Face Rz=40, machined

Form E, Face Rz=16, machined

2. Tongue and groove according to DIN 2512

Form F, Tongue

Form N, Groove

3. Male and Female according to DIN 2513, DIN 2514

Form V13, V14, Male

Form R13, R16, Female

4. Chemfering for diaphragm-weld packings, PN64-PN400, according to DIN 2695

5. Facing for lens-shaped joints, PN64-PN400, according to DIN 2696

Production Capacity & Purchase Details

1. Supply Flange Dimension DN15 – DN2000 (1/2″ – 80″), Forged Flange.

2. Material Carbon Steel: RST37.2, C22.8, S235JR, ST37, P235GH, P245GH, P250GH, ASTM A105

3. Material Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 etc.

4. Flanges Anti Rust: Anti Rust Oil, Black Paint, Yellow Paint Coating, Hot Dipped Galvanized, Cold Galvanized etc.

5. Monthly Output: 3000 tons per Month.

6. Delivery Terms: CIF, CFR, FOB, EXW.

7. Payment Terms: Wire Transfer (T/T), Irrevocable L/C at Sight etc.

8. Minimum Order Quantity: 1Ton or 100Pcs.

9. Quality Guarantee: EN10204 3.1 Certificate, Mill Certificate, Third Party Inspection, Free Replacement Service.

10. Find More Requirements In Flanges Market.