China OEM Buttweld Reducing Tees Supplier – Stainless Steel Pipe – DS PIPE

China OEM Buttweld Reducing Tees Supplier – Stainless Steel Pipe – DS PIPE Detail:

Description

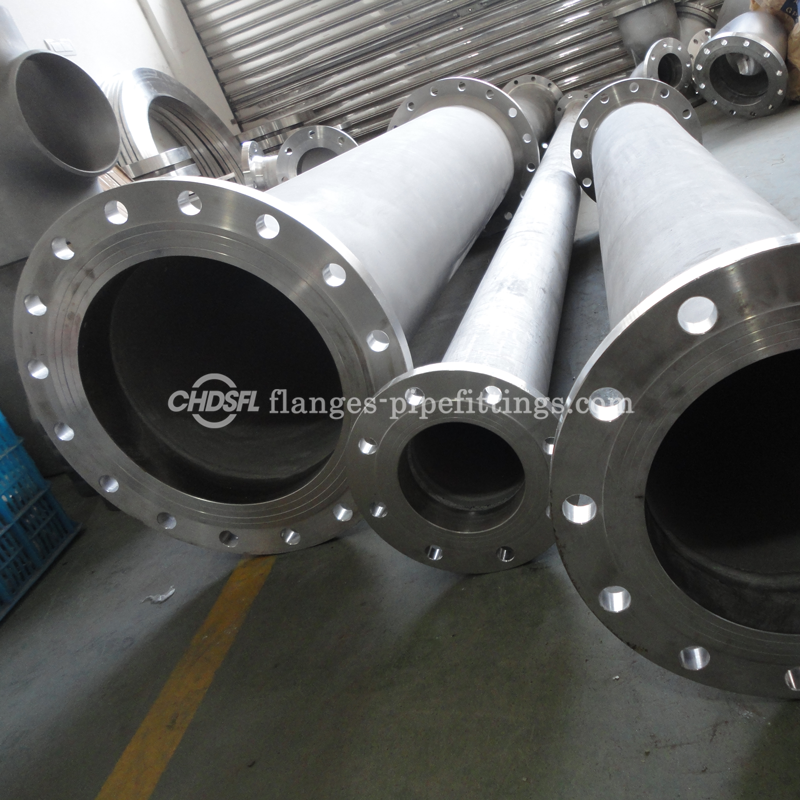

Stainless steel pipe is primarily used in piping systems for the transport of fluids or gases. We manufacture steel pipe from a steel alloy containing nickel as well as chromium, which give stainless steel its corrosion-resistant properties. Stainless steel pipe resists oxidation, making it a low-maintenance solution that is suitable for high temperature and chemical applications. Because it is easily cleaned and sanitized, stainless steel pipe is also desired for applications involving food, beverages, and pharmaceutical applications.

Stainless steel pipe is commonly manufactured using a welding process or extrusion. The welding process involves shaping steel into a pipe shape and then welding the seams together to hold the shape. Extrusion creates a seamless product and involves heating a steel rod and then piercing it through the middle to create a pipe.

The term “pipe” and “tube” are often used to describe the same product, but it is important to know the difference. Though they share the same cylindrical shape, steel pipes are measured by the interior diameter (ID), whereas steel tubes are measured by the outside diameter (OD) and wall thickness. Another difference is that pipes are used to transport fluids and gases, while tubes are used to build parts or structural components.

Stainless Steel Pipes Provide Long-Lasting Durability and Corrosion Resistance.

DS Tubes provides stainless steel pipe that is welded and manufactured to ASTM A-312 and ASME SA-312 and are offered in 304/L and 316/L grades of steel. We generally make our welded stainless pipe in sizes ranging from 1/8″ nominal to 24″ nominal. We also provide seamless stainless steel pipe manufactured to ASTM A-312 and offered in both 304/L and 316L grades of steel. The nominal size range for our seamless stainless pipes typically ranges from 1/8″ – 8″.

Some of the common applications for stainless steel pipe include:

Food processing; Textile operations; Breweries; Water treatment plants; Oil and gas processing; Fertilizers and pesticides; Chemical applications; Construction; Pharmaceuticals; Automotive components.

Product Testing

Part Of The Process

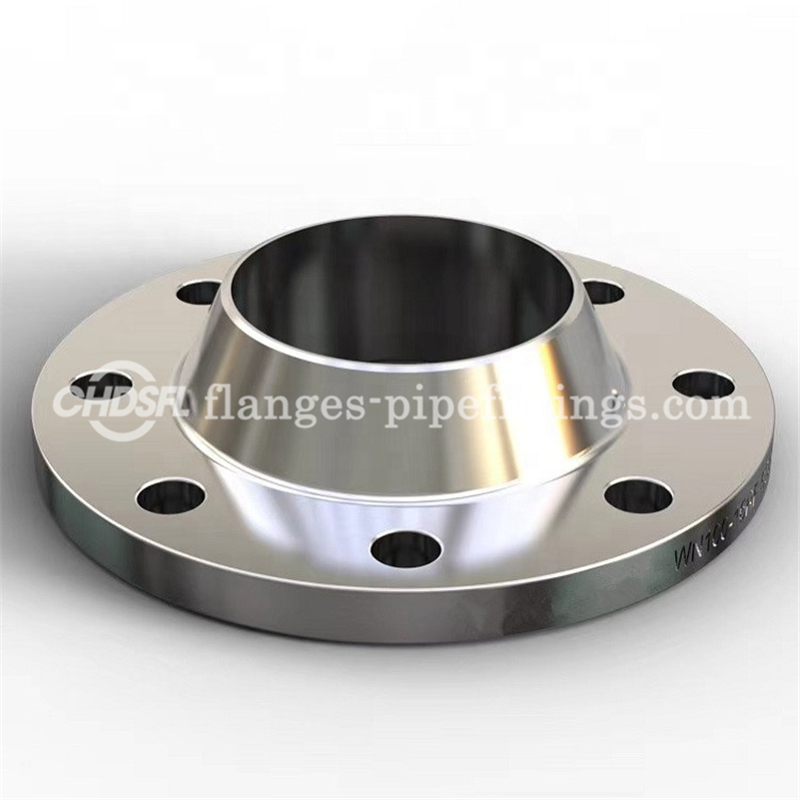

Product detail pictures:

Related Product Guide:

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for China OEM Buttweld Reducing Tees Supplier – Stainless Steel Pipe – DS PIPE , The product will supply to all over the world, such as: Bahrain, Washington, Slovak Republic, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.