Quality Control

Quality Management

The complete management system ensures we make qualified products at the client’s visual angle. Also, external quality control from a third-party inspection is another powerful guarantee for our products —Vendor auditing and Process Inspection are available.

To meet every requirement of our customers and comply with international specifications and dimensional standards, we follow a strict quality policy.

We set up a quality control department which is run by a team of QC experts whose job is to maintain all records and supervise QC inspectors.

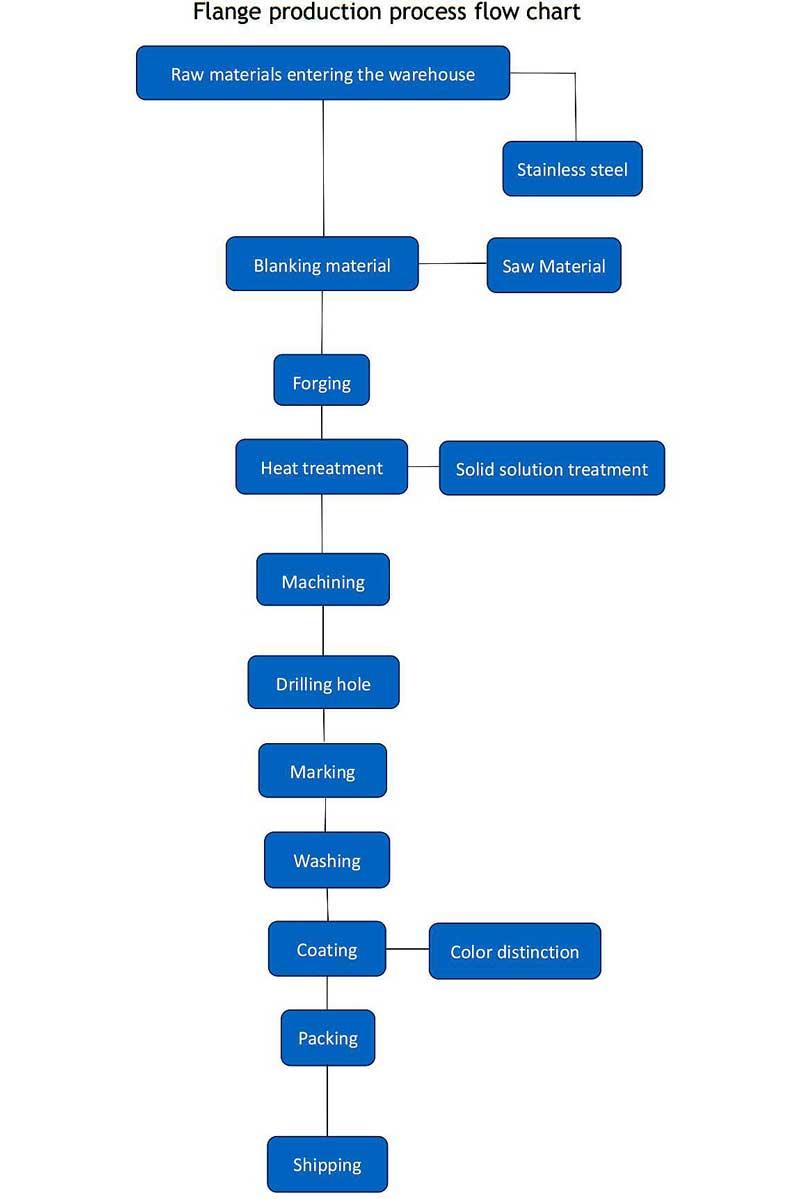

Now, our production capacity can reach 3000tons/month of flanges and 2000tons/month of pipe fittings. Adhering to the spirit of hard struggle since the entrepreneurial stage, we strengthen the internal management and expand the external market, and already formed a complete system of production -inspection -sales - after-sales service. Advanced equipment 、strong techniques、strict technology control system and a perfect after-sales service system, all provide a powerful guarantee for our increased sales performance year by year.

Inspection Tools

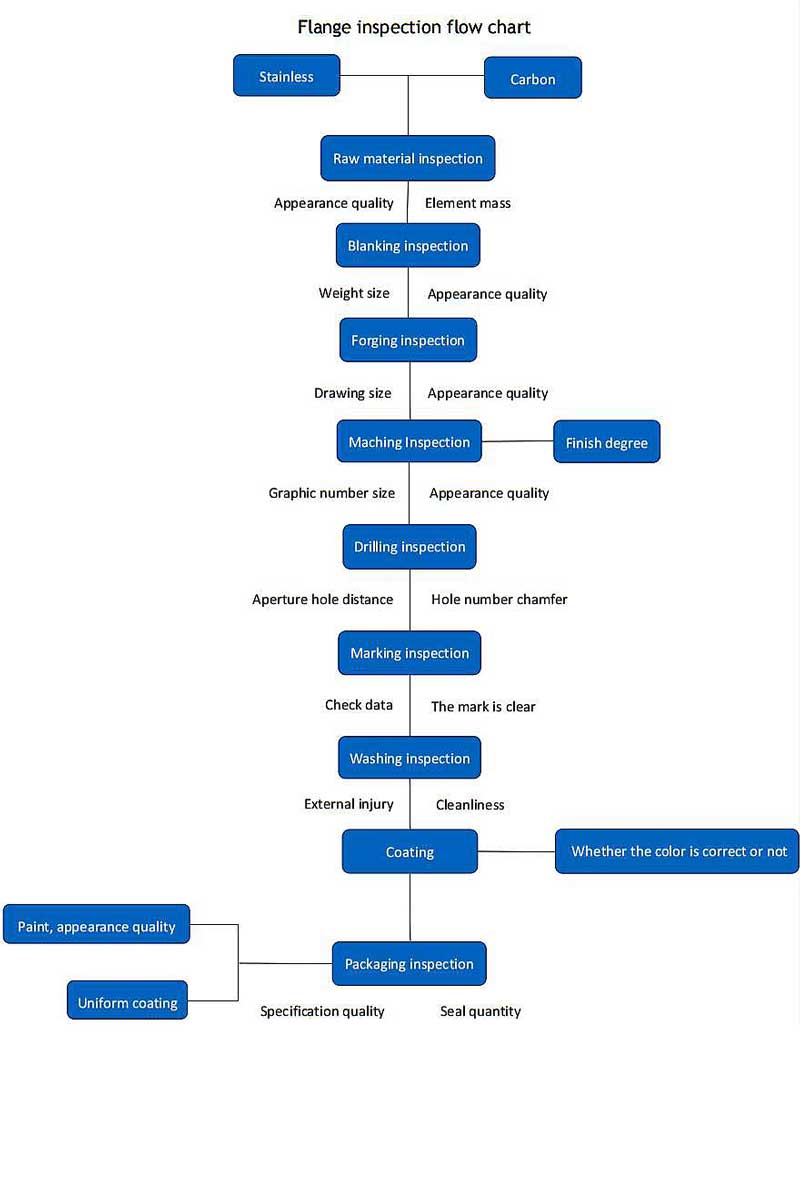

Raw materials Inspection

Besides review of raw materials certificate from the supplier,we also carry out chemical and mechanical inspections for quality verification.We will purchase raw materials from our approved suppliers,if exceeds the range,the relevant qualification procedures must be approved by our quality department first.

Visual inspection in production

Appearance of products in every procedure shall be visual inspected.If there is any deformation or damage found,this product shall be rejected.

Traceability

From raw material to semi-finished products and finished products,good traceability records always are kept. Random inspection for semi-finished products:in each procedure,the random inspection for semi-finished products shall be carry out.There is also another work in this section,material grade verification,color coding shall be made full use of in this regard.

NDT

MPI shall be applicable to each piece of fittings made by cold forming method.100% RT shall be done on weld seam of welded products.Other NDE tests shall be as per clients’ demand and all NDT tests shall only be executed after heat treatment.

Dimensions checking

Sizes and angles for each product shall be inspected according to relevant standard tolerance ranges.

Third party inspection

We also accept any third party inspection appointed by our customers,such as Lloyd’s Register,BV, SGS,TUV,DNV and etc.