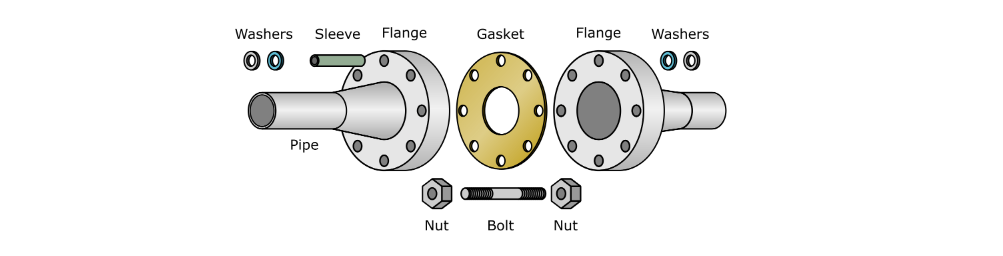

Flange connection, as the name implies, is a joint that tightly connects two flanges at both ends of the pipeline. This joint is easy to disassemble and has good sealing performance.

1 What is a flange connection

Flange connection is actually a kind of joint that connects pipelines to each other, and it is also a way to connect, mainly by fixing two pipe fittings or pipes on two flanges respectively, and then in the middle of the two flanges. Pad a flange washer, and finally tighten the flanges with bolts to make them fit together tightly. This type of connection between pipes is mostly used in cast iron pipes and rubber-lined pipes.

2 Flange connection

Flange connection methods can generally be divided into five types: flat welding, butt welding, socket welding, loose sleeve and thread.

The first four are described in detail below:

Flat welding: only the outer layer is welded, and the inner layer is not required; it is generally used in medium and low pressure pipelines, and the nominal pressure of the pipeline should be lower than 2.5MPa. There are three types of sealing surfaces for flat welding flanges, namely smooth type, concave-convex type and tongue-and-groove type. Among them, the smooth type is the most widely used, and is affordable and cost-effective.

Butt welding: the inner and outer layers of the flange must be welded, generally used in medium and high pressure pipelines, and the nominal pressure of the pipeline is between 0.25 and 2.5MPa. The sealing surface of the butt welding flange connection method is concave and convex, and the installation is more complicated, so the labor cost, installation method and auxiliary material cost are relatively high.

Socket welding: generally used in pipes with nominal pressure less than or equal to 10.0MPa and nominal diameter less than or equal to 40mm.

Loose sleeve: generally used in pipelines with low pressure but relatively corrosive medium, so this type of flange has strong corrosion resistance, and the material is mostly stainless steel.

3 Flange connection process

The flange connection process is as follows:

First, the connection between the flange and the pipeline must meet the following requirements:

1. The center of the pipe and the flange should be on the same horizontal line.

2. The center of the pipe and the sealing surface of the flange form a 90-degree vertical shape.

3. The position of the flange bolts on the pipeline should be the same.

Second, the padding flange gasket, the requirements are as follows:

1.In the same pipeline, the gaskets selected for flanges with the same pressure should be the same, so as to facilitate future exchange.

2. For pipes using rubber sheets, it is best to choose rubber gaskets, such as water lines.

3. The selection principle of the gasket is: choose as close as possible to the small width, which is the principle that should be followed on the premise that the gasket will not be crushed.

Third, the connecting flange

1. Check whether the specifications of flanges, bolts and gaskets meet the requirements.

2. The sealing surface should be kept smooth and tidy without burrs.

3. The thread of the bolt should be complete, there should be no defects, and the fitting should be natural.

4. The texture of the gasket should be flexible, not easy to age, and the surface should not be damaged, wrinkles, scratches and other defects.

5. Before assembling the flange, the flange should be cleaned to remove oil, dust, rust and other sundries, and the sealing line should be removed cleanly.

Fourth, the assembly flange

1. The flange sealing surface is perpendicular to the center of the pipe.

2. Bolts of the same specification have the same installation direction.

3. The installation position of the flange installed on the branch pipe should be more than 100 mm from the outer wall of the riser, and the distance from the wall of the building should be 200 mm or more.

4. Don’t bury the flange directly underground, it is easy to be corroded. If it must be buried underground, it is necessary to do anti-corrosion treatment.

4 Flange connection pictures

Post time: May-19-2022